The construction of the walls of the house from gas blocks

First three rows

We clean the top of the basement from dust and small debris, lay the waterproofing. In our case - ruberoid. Completely, around the perimeter and inner walls. We overlap at the joints. There is not much waterproofing.

Waterproofing on the plinth - preparation for laying the first row of gas blocks.

Laying the first row of walls from the gas block

The first row is laid on a cement-sand mortar so that it is possible to adjust the level of the masonry. The smoother the first row, the smoother the house will be. The beginning of the masonry is the corner. In order to determine which of the available angles will be the first and guide, we are looking for the highest. This is done using the hydro level, since we do not need the exact height of the corner above sea level, but the relative height of all corners. There is a minimum thickness of the mortar layer on which the block can be laid - 1 cm, but there is no maximum. Therefore, you need to align all the corners and move from the topmost to the rest, trying to even out the flaws in the construction of the basement (increasing or decreasing the cement layer if necessary).

In addition, it is necessary to align the geometry of the building so that our aerated concrete house is still rectangular, and not a trapezoid or a rhombus. Everything may seem perfect to the eye, but if you pick up a tape measure, there will be minor flaws that can still be corrected at this stage. We measure the diagonals one by one. They must be the same. If there is a difference, we look and, if possible, note where and how much it is necessary to move the block so that it becomes even. The process is long and tiring, but worth it!

As soon as we have decided on the height of the corners, we outline the future wall with a fishing line. The ideal option is when it is possible to move the edges of the stretched fishing line beyond the base. Then even the very first block will be laid beautifully and correctly. If this is not possible, we begin to build by eye. We lay the first block, in the remaining corners we put the blocks simply on the roofing material and pull the fishing line.

As mentioned above, we put the first row of walls from the gas block on a cement-sand mortar, armed with a level and a rubber mallet.

Why on cement, if there is a special glue for blocks:

- it is possible to vary the thickness of the layer on which the masonry is made;

- glue is good on flat surfaces, and the top of the plinth, no matter how hard you try, did not turn out perfectly even. Cement-sand mortar will perfectly smooth out all the bumps.

I emphasize once again that it is necessary to verify the evenness of each laid gas block using a level in all directions - both horizontally and vertically.

Blocks were laid along the entire perimeter and inner walls, not forgetting the doorways. Of course, they must be skipped.

As mentioned above, they were built from blocks with a tongue-and-groove fastening. They were chosen because they have handles in their design - it is more convenient to carry, and there is no need to coat the sides with glue. Due to the tongues and grooves, the wall is quite strong even without it. If you build walls from a smooth block, then do not forget that you need to glue the side parts with glue. And in the case of the first row - fasten with a cement-sand mortar.

To simplify and speed up the process of further laying of gas blocks, they were moved inside the rooms. Ideal if the forklift can immediately unload pallets of aerated concrete blocks into the middle of the future house.

Blocks inside rooms.

Second and third rows

Before proceeding with the further laying of aerated concrete, we grind the surface of the first row by polishing. We repeat this procedure before each new row.

This is done so that the surface on which the glue will be applied is as even as possible - this will ensure the best adhesion of the blocks. The layer of glue required for laying the walls of the house is quite thin (0.5-0.7 cm). If a corner of the block sticks out somewhere, at least not a lot, the next row will “play”.

We lay the second and third rows of the walls of the house from gas blocks on glue, starting from the corners. Be sure to do the dressing of the rows, as in brickwork, to get a half-block shift. The minimum shift for gas block masonry is 8 cm.

Laying on glue is much faster and easier than on cement: we apply glue with special ladles with cloves, put the block as close to the previous one as our fingers allow, and push it back to back. It is important to continue to check the evenness of the masonry. If necessary, adjust with a rubber mallet. All manipulations must be carried out as quickly as possible - the glue dries quickly and you may have to tear off the stacked block in order to fix something.

Reaching the doorways, it is not always possible to hit exactly the length of the block. This is not a problem - aerated concrete is perfectly sawn with a conventional hacksaw for wood with set teeth. It is not at all necessary to buy expensive special saws for a gas block. Any ordinary one will do, the only thing that can simplify the sawing process is the length of the teeth. The longer, the easier. But the corner is a necessary thing for an even cut.

Windows and window sills

In our case, the height of the window sill is almost everywhere - 4 rows of aerated concrete. It is necessary to reinforce window openings one row below the window sill. When the perimeter of the third row is ready, it's time to mark and reinforce the windows. To do this, they used a tool called a wall cutter.

We pierced two parallel lines that go beyond the future window by 30 cm on each side.

The reinforcement was laid, fixed with a cement-sand mortar. Thus, we strengthened the wall, in which there will be an opening for the window.

Door and window lintels

Our aerated concrete house is growing, we are approaching the lintels. We need them to strengthen the wall above the door or window opening so that further construction does not collapse. They can be done in several ways:

- order ready. There are already ready-made jumpers on sale, and there are prepared formworks, the so-called U-shaped blocks, which can be used for these purposes. They glued the desired length, put it in place, laid the reinforcement, poured it with cement. But they must be ordered separately.

- make formwork from blocks yourself. To do this, you need blocks with a width of 100 mm. They stick together very well with the same glue. Such a jumper must be supported so that the cement poured inside does not break it. If there is no place to order "tens", you can cut a regular block lengthwise into three parts.

- build a jumper from ordinary blocks. Blocks were glued together, three longitudinal ditches were drilled, reinforcement was laid, and cement-sand mortar was poured. Leave alone until the solution has completely set (about a day). You need to install the fittings down. But such jumpers are suitable only for narrow openings (no more than 1 m), since the shift of the block relative to the previous row must be at least 8 cm.

First, we lay the jumper in its place, and then we lay the gaps with gas blocks of the desired size.

armored belt

The row in which the window lintels were laid is completed. Now you can fill in the armored belt, it is also called the seismic belt. This is a layer of reinforced concrete that must hold the integrity of our aerated concrete structure.

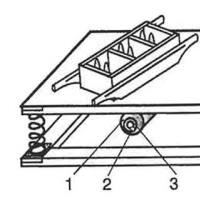

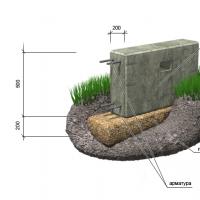

We lay blocks of 100 mm along the perimeter in two rows, forming a formwork.

![]()

Formwork for armored belt

We put reinforcement in the resulting ditch, fill it with cement-sand mortar. The house will have an attic floor and it is desirable that the roof does not fly away. To do this, studs were embedded in the armored belt, on which the Mauerlat (“foundation” for the roof) will be attached. They can be made from ordinary fittings, or with threaded threads. This will greatly simplify the mounting of the Mauerlat in the future.

OK it's all over Now. The first floor of the house is built of aerated concrete. You can take a break.